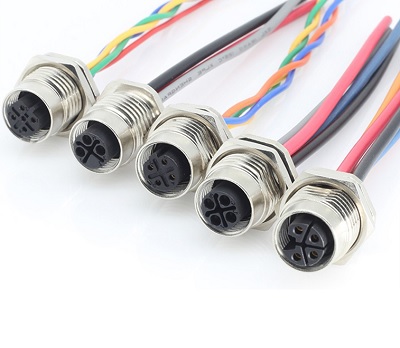

Including M5 to M23 connector and cable, IP67 waterproof level

Include waterproof RJ45, USB A, USB C and D sub. IP67 waterproof level

Include HPCN, HPDB, VHDCI connectors, video and audio transmission

High current connector single pole, multi pole, compliance to Anderson and Rema brand power connectors

Customized solutions of cable assembly and wire harness. Include automotive, industrial control, home appliance and medical cables.

Cable and connector accessories, like contact pins, metal parts, raw cable.

FlexContac Technology Co., Ltd has been developing, producing and marketing industrial connectors and patch cable assemblies as well as customized wiring harnesses. We can provide hardware and plastic electronic products and components research and development services, waterproof product structure design services, Pro/E 3D design services, CAD design services and prototype manufacturing. Our high-tech experts and engineering teams are dedicated to providing interconnected solutions.

READ MOREProfessional provider of complete solutions for wire harness processing

With over 20 years of experience, we are a trusted and established manufacturer in the industry.

ISO 9001, IATF16949 and UL certified, and products are RoHs and Reach compliant.

Keep investing in R & D, explore new technologies and innovations to offer cutting-edge solutions.

Professional team, experienced engineers. Sincerely treat every customer and every order.

Offer end-to-end services, from design to mass production, providing a complete solution for our customers.